Applied Sciences, Free Full-Text

$ 17.50 · 4.6 (715) · In stock

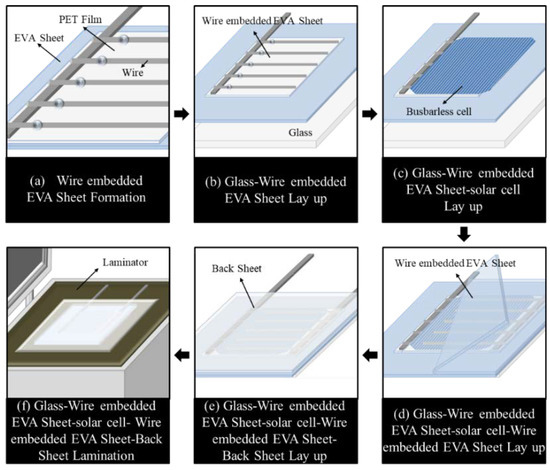

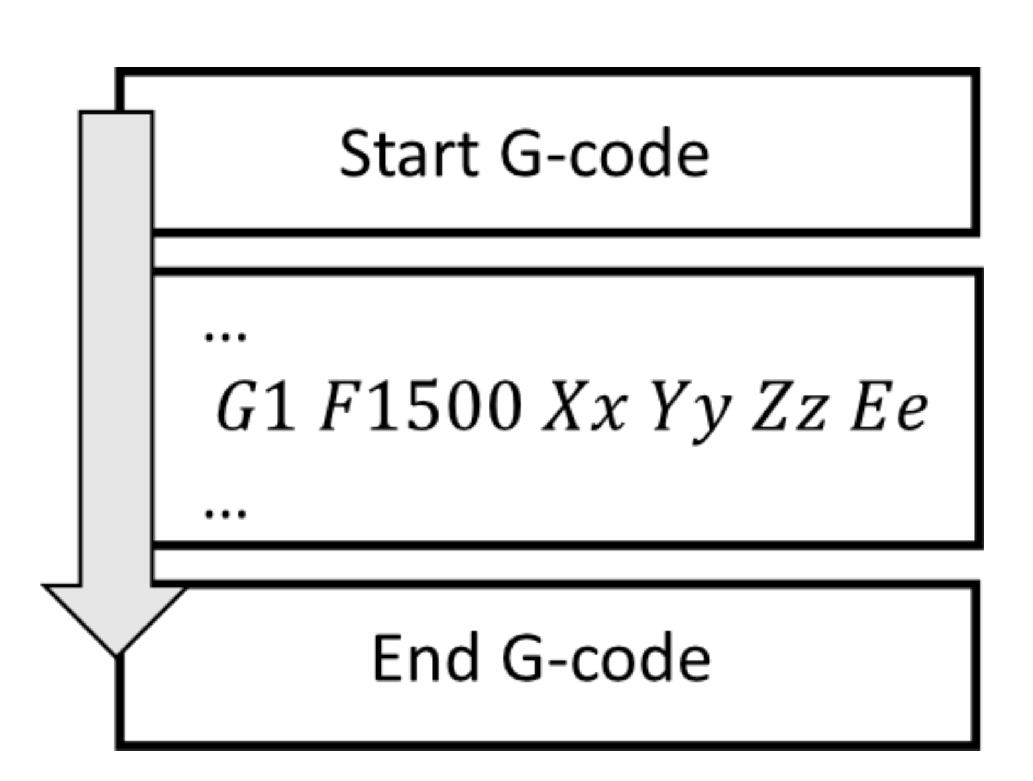

Silicon wafers are crucial for determining the price of solar cell modules. To reduce the manufacturing cost of photovoltaic devices, the thicknesses of wafers are reduced. However, the conventional module manufacturing method using the tabbing process has a disadvantage in that the cell is damaged because of the high temperature and pressure of the soldering process, which is complicated, thus increasing the process cost. Consequently, when the wafer is thinned, the breakage rate increases during the module process, resulting in a lower yield; further, the module performance decreases owing to cracks and thermal stress. To solve this problem, a module manufacturing method is proposed in which cells and wires are bonded through the lamination process. This method minimizes the thermal damage and mechanical stress applied to solar cells during the tabbing process, thereby manufacturing high-power modules. When adopting this method, the front electrode should be customized because it requires busbarless solar cells different from the existing busbar solar cells. Accordingly, the front electrode was designed using various simulation programs such as Griddler 2.5 and MathCAD, and the effect of the diameter and number of wires in contact with the front finger line of the solar cell on the module characteristics was analyzed. Consequently, the efficiency of the module manufactured with 12 wires and a wire diameter of 0.36 mm exhibited the highest efficiency at 20.28%. This is because even if the optical loss increases with the diameter of the wire, the series resistance considerably decreases rather than the loss of the short-circuit current, thereby improving the fill factor. The characteristics of the wire-embedded ethylene vinyl acetate (EVA) sheet module were confirmed to be better than those of the five busbar tabbing modules manufactured by the tabbing process; further, a high-power module that sufficiently compensated for the disadvantages of the tabbing module was manufactured.

Applied Science

Official electronic signature

Applied Sciences, Free Full-Text, Synthetic Dye

Applied Sciences, Free Full-Text, Synthetic Dye

Full text access through Strategian - Strategian Science

Applied Sciences, Free Full-Text, groups moodle ufsc

Applied Sciences, Free Full-Text, g1 f1500

Applied Sciences, Free Full-Text, car accelerator pedal

Applied Sciences, Free Full-Text, g1 f1500 e0

University Of Applied Sciences for Media, Communication

Applied Science Fiction Vector Logo - Download Free SVG Icon

Sources for technology and business insights explained, part 4/7